Injection moulding style and design companies Perform a very important part in reworking Suggestions into significant-top quality plastic areas All set for mass generation. No matter whether you are acquiring a wonderful your self or bettering a existing ingredient, Experienced design services keep your moulded components are successful to produce, cost-successful, and fulfill efficiency anticipations.

Exactly what are Injection Moulding Design Solutions?

Injection moulding structure products and services include the planning, engineering, and planning of the part or merchandise made for the injection moulding course of action. This includes almost everything from initial 3D modelling and CAD (Laptop-Aided Structure) drawings to prototyping and finalising mould design. The intention would be to make a style and design that actually works properly flawlessly with injection moulding machinery though preserving performance, longevity, and aesthetic charm.

Essential Features of the look System

Quite a few things should be viewed as when coming up with for injection moulding:

Material assortment: Deciding on the correct plastic is important. Various polymers supply special Qualities, as an example energy, versatility, warmth resistance, or transparency.

Wall thickness: Uniform wall thickness stops concerns like warping, sink marks, or incomplete mould fills.

Draft angles: Such as slight angles in the structure assists sections eject effortlessly in the mould with no problems.

Ribs and managers: These functions incorporate power and help to areas without increasing product use or weight.

A nicely-designed part not simply improves general performance but On top of that cuts down creation charges and cycle moments.

The Value of Qualified Designers

Doing work owning an knowledgeable injection moulding style workforce guarantees your item is ready for productive manufacturing. These authorities look at the complexities of toolmaking, production machining, and resources science, and so that they will help refine your design and style so as to keep away from expensive issues Sooner or later.

Firms like Australian Consolidated Plastics offer you entire design-to-creation expert services. Their in-property crew utilizes State-of-the-art software to generate precision equipment and dies, making sure each and every part satisfies limited tolerances and quality specifications. This whole-service strategy saves time, improves accuracy, and accelerates time for you to market place.

From Prototype to Generation

Structure services can guide you to definitely prototyping to test kind, suit, and function prior to whole-scale manufacturing starts. This permits customers to acknowledge and fasten challenges early, saving both equally time and money in the long term.

Conclusion

Injection moulding layout companies definitely can be a crucial move within production journey. By buying good, efficient layout, companies can make sure their plastic parts are creation-Prepared, Price tag-productive, and built to last. With the more info appropriate layout companion, your strategy is usually a industry-ready reality.

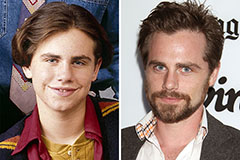

Rider Strong Then & Now!

Rider Strong Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Nancy Kerrigan Then & Now!

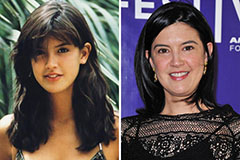

Nancy Kerrigan Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!